Get to Know the Indonesian Wet-hulled Coffee Process

The wet-hulled process, known locally in Indonesia as Giling Basah, significantly impacts the flavor profile and overall character of the coffee. Unlike traditional washed or natural methods, wet-hulling involves removing the parchment layer from the coffee bean while it is still wet, resulting in quicker drying under humid conditions. Most of the Indonesian Coffee uses this as the processing method.

In this article, we will share with you how the wet hulled process is implemented for Aceh Gayo Coffee at our Indonesia Specialty Coffee Processing Plan in Desa Bintang Permata, Bener Meriah, Aceh.

Let’s dive deeper into the Giling Basah a.k.a Wet Hulled process.

Understanding the Wet-Hulled Process

The Wet-Hulled process begins similarly to other coffee processing methods, with the depulping of the coffee cherries. This initial step involves mill workers de-pulping sacks of coffee cherries using a Pulper Machine, a process conducted as soon as possible to maintain the coffee’s quality.

The de-pulped seeds, still covered in their mucilage, are then placed in a fermentation tank overnight (12 Hours) and then washed. This controlled fermentation is a distinctive feature at most of the Sumatra Coffee Mill, where there is oversight over each step from start to finish.

Pre-Drying: Preparing for Wet-Hulling

Before the coffee can undergo Wet-Hulling, it requires a quick pre-drying phase. The seeds are raked into thin layers and left to dry for several hours to a full day, depending on the prevailing humidity and cloud cover. This pre-drying is crucial, as it reduces the seeds’ moisture content to about 30–35%, making them ready for the Wet-Hull process.

Wet-Hulling: The Core of the Process

The essence of Wet-Hulling lies in removing the parchment layer from the coffee seeds before they are fully dry. This contrasts with other methods where the parchment remains on the seeds until they are ready for export. The Wet-Hulling machine, similar in operation to a depulper but calibrated differently, removes the parchment layer efficiently.

In regions with less humid climates, the parchment serves to protect the coffee seeds against moisture and temperature fluctuations. However, in Indonesia’s humid and cloudy environment, removing the parchment early allows for more effective drying. Despite its benefits, Wet-Hulling is somewhat traumatic for the seeds, often resulting in some being chipped, crushed, or split.

Post-Hulling Drying and Final Preparation

Once Wet-Hulling is complete, the coffee seeds, now green coffee beans, are further dried. The seeds are spread out on tarps on concrete and raked into thin layers. This drying process exposes the seeds to sunlight, heat, and air, which are critical for drying in Indonesia’s humid climate. The unique earthy, savory, and herbaceous flavors characteristic of Indonesian coffees, particularly those from Sumatra, are largely attributed to this processing method, alongside the specific cultivars and regional climate.

The final stage involves drying the coffee to a moisture content of 11–12%. The dried coffee is then bagged and stored in a warehouse until it is ready to be shipped. This meticulous process ensures that Wet-Hulled coffee retains its distinctive profile, making it a sought-after product in the global coffee market.

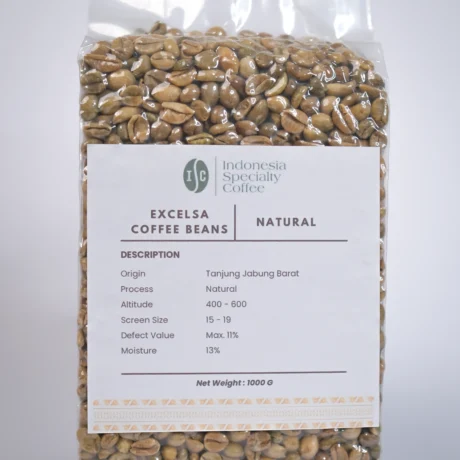

Get wet-hulled green coffee beans from us!

Email us at info@specialtycoffee.id or WhatsApp at +62 811 6380 606