Ever wonder why some coffee tastes like berries, while others feel earthy and bold? The answer lies in coffee processing methods. Before your beans are roasted and brewed, they go through a transformation that shapes every note in your cup. Whether you’re sipping a bright pour-over or a full-bodied espresso, understanding how coffee is processed helps you choose the flavor you love most.

Coffee processing methods shape everything from sweetness and body to acidity and aroma. Whether you love fruity pour-overs or bold, earthy espresso, the journey from dry to fermentation defines your coffee experience. Let’s dive into this flavorful world and uncover what truly sets great coffee apart.

What Are Coffee Processing Methods, and Why Should You Care?

Coffee processing methods refer to how farmers remove the layers of skin, pulp, and mucilage from the coffee cherry to reveal the bean. Each method—whether dry, wet, honey, or semi-washed—produces a distinct flavor profile. This is the foundation of your coffee’s body, aroma, and taste.

But processing isn’t just a technical step. It’s an art form that influences the final taste of your brew. Some methods bring out bright, fruity notes, while others deepen the body and richness.

If you’ve ever seen “natural,” “washed,” or “honey-processed” on a label and wondered what it meant—this guide is for you.

1. Natural or Dry Process – The Oldest of All Coffee Processing Methods

The natural process, also called dry processing, is the oldest method, dating back to Ethiopia. It’s rustic, sun-kissed, and full of character.

Here’s how it works:

- Whole cherries are dried under the sun for weeks.

- As the fruit ferments, sugars seep into the bean.

- Once dry, the beans are hulled to remove the outer layers.

Flavor profile: Expect bold, fruity, sometimes wine-like flavors. It’s the method behind many juicy, sweet coffees—but beware, if poorly handled, it can taste fermented or funky.

Want to explore coffees processed this way? Check out our Sumatra coffee guide for bold Indonesian profiles using similar traditional techniques.

Flavor Notes of Natural Coffee

Natural-processed beans bring fruity, wine-like notes to your cup. This method lets the cherry dry whole under the sun, allowing sugars from the fruit to soak into the bean—an essential characteristic in many beloved coffee processing methods.

2. Washed Process – Clean, Bright, and Popular Worldwide

On the opposite end of the spectrum is the washed or wet process. It’s all about clarity and control.

How it works:

- Cherries are depulped right after picking.

- Beans are soaked in water to remove mucilage.

- Then they’re dried under the sun, turned regularly.

Flavor profile: Washed coffees highlight the bean’s origin—think clean citrus, floral notes, and high acidity. This is the go-to for those who love precision in every sip.

For a beautifully balanced cup, learn about perfect coffee measurements to brew washed coffees to their full potential.

The Role of Fermentation in Washed Coffee

Fermentation is critical in washed coffee processing methods, helping separate mucilage from the bean for a cleaner taste. This method highlights a coffee’s origin rather than the process.

3. Honey Process – A Sticky, Sweet Middle Ground

Despite the name, honey-processed coffee doesn’t use actual honey. Instead, the term refers to the sticky, sugary mucilage left on the bean during drying.

Process breakdown:

- Cherries are pulped, but mucilage isn’t washed off.

- Beans are dried with this layer intact.

- Depending on how much mucilage remains, you get red, yellow, or black honey.

Flavor profile: A beautiful balance—fruitier than washed, but cleaner than natural. Think honey, caramel, and subtle fruit.

This process is popular in Costa Rica and El Salvador—but Indonesian beans are catching up fast. For adventurous brewers, this method offers the best of both worlds.

Curious how to extend that sweet aroma? Learn how to store your coffee beans the right way.

Honey Coffee and Its Subcategories

Among all coffee processing methods, the honey process offers one of the most balanced flavor experiences—less fruity than natural, more rounded than washed.

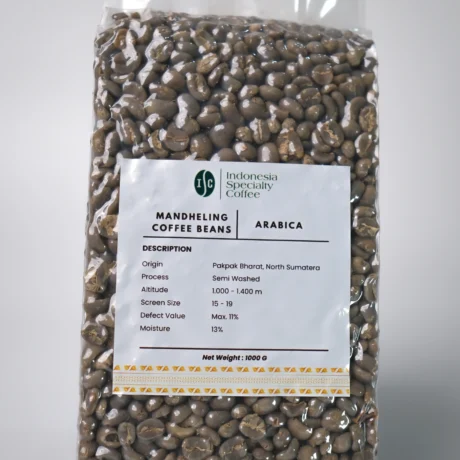

4. Wet-Hulled (Giling Basah) – Indonesia’s Signature Coffee Processing Method

This semi-washed method is used primarily for Indonesian beans and produces the country’s signature bold, low-acidity flavor. Among Southeast Asia’s unique coffee processing methods, wet-hulling stands out for its distinctive earthy profile.

How it works:

- Cherries are pulped and briefly fermented.

- Beans are hulled at high moisture (~30%).

- Then they undergo a second sun-drying stage.

Flavor profile: Heavy-bodied, low-acid, earthy, and spicy. Think of those rich, mysterious flavors found in Sumatran or Torajan coffee.

Learn more about the magic behind Toraja coffee’s rich character.

5. Wine Process – Where Coffee Meets Complexity

Wine process (sometimes referred to as winey fermentation or experimental processing) is one of the most innovative and adventurous coffee processing methods in the specialty world today. It takes inspiration from wine fermentation techniques—especially carbonic maceration and anaerobic fermentation—to create rich, complex flavor profiles that push the boundaries of what coffee can taste like.

How It Works:

- Ripe coffee cherries are placed in sealed tanks, often without oxygen (anaerobic conditions).

- Inside, a controlled fermentation occurs—sometimes lasting days or even weeks.

- After fermentation, the coffee is dried slowly, often still in its mucilage or even whole-cherry form.

Flavor Profile:

Expect a deep, wine-like acidity, layered complexity, and unexpected notes like dark berries, spice, and tropical fruit. These coffees can be polarizing—wild and fruity for some, too funky for others—but they’re always an experience.

This method is especially popular among experimental producers in Colombia, Ethiopia, and Panama, but Indonesian micro-lots are starting to explore wine-style fermentation too.

Why Does Coffee Processing Matter to You?

Because the processing method changes everything.

- Want sweet and syrupy? Try natural process.

- Prefer clarity and floral notes? Go washed.

- Looking for something in-between? Honey process is your friend.

- Craving earthy, bold tones? Wet-hulled Indonesian coffee is your match.

- Ready for bold, experimental flavors? Dive into the wine process—perfect for those who love deep fruit notes, funky aromas, and a touch of wild complexity in their cup.

It’s not just about caffeine—it’s about choosing the flavor adventure that fits your mood, brew method, and personality.

And if you’re just getting started, discover how brewing time affects your pour-over for even more control over your cup.

Choosing Your Favorite Coffee Based on Processing Methods

When buying specialty coffee, don’t just look at the origin—check the label for the processing method.

Here’s a quick cheat sheet:

| Method | Best For Fans Of | Typical Flavors |

|---|---|---|

| Natural | Fruit-forward, juicy brews | Berry, winey, sweet |

| Washed | Clean, high-acidity coffees | Citrus, floral, tea-like |

| Honey | Balanced, smooth flavors | Honey, brown sugar, stonefruit |

| Wet-Hulled | Bold, earthy espresso lovers | Tobacco, cedar, spice |

| Wine Process | Funky, experimental coffee lovers | Red wine, dark berries, tropical fruit, spice |

Want to explore further? Check our guide to specialty coffee processing and find what suits your palate.

Final Sip: What’s in Your Cup Tomorrow?

Next time you drink your coffee, pause and think—was this bean dried under the sun or fermented in water? Was it left sticky with mucilage or hulled wet in a mountain village in Sumatra?

Understanding coffee processing methods brings a deeper appreciation for every cup. It connects you to the farmer, the land, and the craft behind every bean.

So tell us—what’s your favorite flavor in coffee, and which processing method will you try next?

Explore More:

- Indonesia Specialty Coffee – Which One is the Best?

- Where to Find Raw Coffee Beans

- Sustainable Coffee Production

- Sumatra Coffee Taste Characteristics

Let your coffee curiosity lead the way. ☕