What is Anaerobic Processing?

Anaerobic processing is the fermentation of coffee in a completely oxygen-free environment. Instead of being exposed to open air like in traditional (aerobic) fermentation, coffee cherries or de-pulped beans are sealed inside airtight tanks.

As fermentation begins, naturally occurring yeast and bacteria consume the sugars in the coffee’s mucilage. But because oxygen is absent, the process changes. Carbon dioxide (CO₂) builds up inside the tank, creating a pressurized environment that forces flavors deeper into the beans.

This pressure, combined with unique microbial activity, leads to the production of different organic compounds — particularly lactic acids — that dramatically shape the final flavor. Depending on the producer’s approach, the outcome can range from fruit-forward and wine-like to rich, creamy, or sparkling with unusual aromas.

In short, anaerobic processing is a deliberate way of controlling fermentation to unlock flavors that traditional methods cannot easily achieve.

How Fermentation Works in Coffee

Fermentation is a natural process that begins the moment coffee cherries are picked. The combination of sugars, acids, water, yeast, and bacteria triggers a chain of biochemical reactions that transform the coffee’s chemistry.

In simple terms, microorganisms feed on the sugars in the mucilage (the sticky layer surrounding the bean) and produce alcohol, carbon dioxide, and a variety of organic acids. These reactions directly shape the coffee’s flavor, aroma, and overall complexity.

Traditionally, this happens in an aerobic environment (with oxygen). Oxygen allows certain microbes to thrive, producing bright, clean, and often fruit-balanced profiles that are well known in washed, honey, and natural coffees.

By contrast, anaerobic fermentation changes the environment entirely. The absence of oxygen slows microbial activity, giving producers more control over how the process evolves. Different acids — such as lactic acid — develop under these conditions, resulting in flavors that are more exotic, unusual, and often bolder than what you’d find in a standard cup.

Anaerobic Processing Step by Step

While the exact approach may vary by farm or producer, the core steps of anaerobic coffee processing follow a similar pattern:

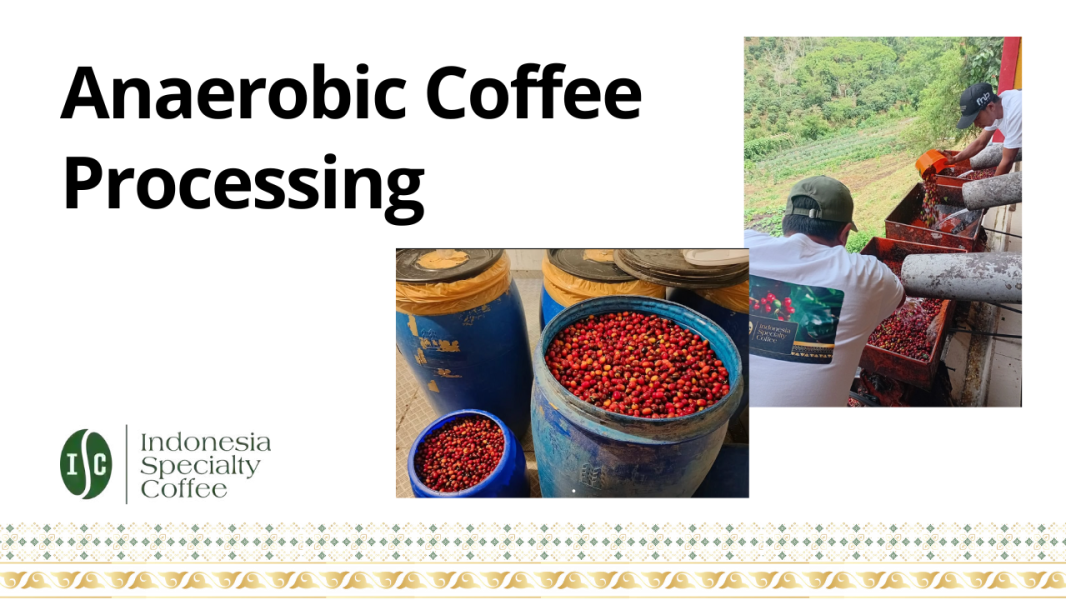

- Harvesting

- Ripe coffee cherries are carefully hand-picked to ensure uniform quality.

- Sealing in Tanks

- The cherries (or de-pulped beans with mucilage still attached) are placed into airtight, sealed tanks.

- Oxygen is excluded, creating an anaerobic environment.

- Fermentation

- As fermentation begins, microbes consume sugars and acids.

- CO₂ builds up inside the tank, creating pressure.

- Pressure forces juices and sugars deeper into the bean, enhancing flavor absorption.

- Managing Pressure and Oxygen

- Release valves allow producers to carefully control CO₂ buildup and release any remaining oxygen.

- This balance helps prevent over-fermentation or unwanted flavors.

- Drying

- After fermentation, coffee can follow different paths:

- Anaerobic Natural → fermented in cherry, then dried whole.

- Anaerobic Honey → fermented in mucilage, then dried with mucilage still on the bean.

- Anaerobic Washed → fermented, then washed and dried clean.

- After fermentation, coffee can follow different paths:

The result is a coffee that not only undergoes a unique transformation inside the tank but also expresses distinct flavors depending on how it is dried afterward.

Variations and Experiments

One of the most exciting aspects of anaerobic processing is its flexibility. Producers can adjust how long the coffee ferments, what stage it’s in during fermentation, and even combine it with other methods. This creates nearly endless possibilities for flavor exploration.

- Single vs. Double Fermentation

Some producers here in Indonesia, use a two-stage approach: first fermenting the whole cherry, then fermenting again after depulping in the mucilage. This layered process adds complexity and depth to the final cup. - Fermentation Times

In aerobic fermentation, things move quickly about 12 hours. But in anaerobic tanks, the absence of oxygen slows microbial activity. This means producers can experiment with much longer fermentation times — from 12 hours to as long as 7 days. Extended time allows unique acids and aromatic compounds to develop. - Natural, Honey, or Washed

Anaerobic processing doesn’t belong to just one style. Producers can apply it to naturals (fermenting whole cherries), honeys (fermenting in mucilage), or washed coffees (fermenting after depulping and washing). Each variation brings out a different expression of the coffee.

These experiments are what make anaerobic processing so dynamic. No two producers — and often, no two batches — will taste exactly the same. So if you are liking the sample of a batch, you surely need to buy as much as you can for that batch of coffee.

Flavor Profile and Cup Experience

Anaerobic coffees are known for their bold, exotic, and often surprising flavors (can be nice complex fruity flavor, berries, citrus, orange or lemon flavor) that stand apart from traditional profiles. The sealed, oxygen-free fermentation allows for the creation of lactic acids and other unique compounds that don’t typically form in aerobic processes.

In the cup, this often translates to:

- Fruity intensity → tropical fruits, berries, and citrus-like brightness.

- Wine-like notes → rich, fermented characteristics similar to red wine.

- Creamy or sparkling textures → unusual mouthfeel, sometimes silky or effervescent.

- Fragrant aromatics → floral, spiced, or candy-like aromas that make the coffee stand out.

Compared to washed or natural coffees, anaerobic lots can feel more experimental and daring, sometimes polarizing, but always memorable. For adventurous coffee drinkers, anaerobic process coffee deliver an experience that feels more like tasting innovation than just drinking coffee.

The Challange of producing Anaerob Coffee

While anaerobic processing offers incredible potential, it also comes with its own set of challenges.

- Consistency

- Fermentation is a living process, and in an oxygen-free environment, outcomes can be unpredictable.

- Even with careful control of time, temperature, and pressure, no two batches may taste exactly alike.

- Risk of Over-Fermentation

- Longer fermentation times mean there’s a fine line between developing complex flavors and producing unwanted defects.

- If not managed properly, flavors can turn sour, overly alcoholic, or unbalanced.

- Infrastructure Demands

- Airtight tanks, valves, and monitoring equipment add extra costs for producers.

- Not all farms can easily implement anaerobic methods.

- Market Perception

- While specialty buyers often love experimental coffees, not every consumer is ready for the bold, unconventional flavors.

- This makes anaerobic lots more of a niche product compared to traditional washed or natural coffees.

Despite these challenges, many producers see anaerobic processing as a creative frontier worth exploring. For them, the risks are balanced by the potential to create something truly remarkable.

The Summary

Anaerobic processing represents one of the most exciting innovations in modern coffee. By fermenting without oxygen, producers are able to push beyond traditional methods and create flavor experiences that are bold, exotic, and unforgettable.

What makes this process so special is its spirit of experimentation. From adjusting fermentation times to layering multiple stages, every producer brings their own creativity to the method — and every batch tells a different story in the cup.

For coffee lovers, tasting an anaerobic lot isn’t just about drinking coffee. It’s about discovering what happens when curiosity, science, and craftsmanship come together. Anaerobic processing reminds us that coffee is always evolving, and that the next unforgettable flavor might be waiting inside a sealed tank, ready to surprise us.